How to Create a Rock-Solid Woodworking Bench (Step-by-Step Guide)

A good woodworking bench is the heart of any workshop. Whether you're a hobbyist or a professional, a solid, well-designed bench gives you the stability and features you need to work efficiently and safely.

In this blog, we’ll walk through how to build a traditional, sturdy woodworking bench with a thick hardwood top, strong base, and optional vise support. Diagrams and visual guides are included to help every step of the way

🧰 Materials & Tools

Materials:

2x Hardwood butcher block or laminated hardwood boards for benchtop

4x4 or 6x6 posts for legs

2x6 boards for stretchers

Wood glue

Wood screws / lag bolts

Vise (optional)

Drawer slides & plywood (optional for storage)

Tools:

Circular saw or table saw

Drill/driver

Clamps

Chisel

Sander

Measuring tape

Square

Wood finish (e.g., linseed oil or polyurethane)

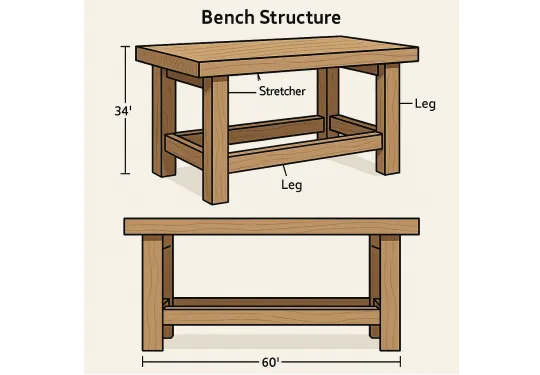

Here’s a basic diagram of the bench structure:

📐 Bench Design Overview

Dimensions:

Height: ~34" (adjust to your comfort)

Top: 60" x 24" x 2.5"

Legs: 4x4 posts

Stretchers: 2x6 boards

Step 1: Build the Base Frame

Cut the Legs: Cut 4 legs from your 4x4 or 6x6 posts (around 32–34” long).

Cut the Stretchers: Use 2x6 boards to connect the legs — two for the top and two for the lower shelf support.

Join the Frame: Use lag bolts or wood screws to attach the stretchers to the legs. Reinforce with wood glue.

Add Bottom Shelf (Optional): Add a plywood panel across the lower stretchers for tool storage.

Step 2: Prepare and Install the Benchtop

Glue Up Boards (if not using a pre-made top): Clamp multiple hardwood boards edge-to-edge using glue.

Sand Smooth: Use a belt or orbital sander to flatten and smooth the top.

Attach Top to Base: Secure the benchtop to the base using screws from underneath. Ensure it's centered and square.

Step 3: Add Vise (Optional)

Choose either a front vise or end vise.

Use a Forstner bit and chisel to create mounting recesses for the vise hardware.

Attach securely to the front corner of the bench.

Step 4: Finish the Bench

Apply linseed oil, tung oil, or polyurethane.

Let it cure for 24–48 hours.

Optionally, add dog holes, tool tray, or T-track system later on.

🗂️ Optional Add-ons

Drawers: Use ¾" plywood and metal slides to install a drawer system underneath.

Power Strip: Mount a power strip to the side for easy access to tools.

Casters: Add lockable casters if you need mobility.

🧪 Final Thoughts

A handmade woodworking bench will outlast anything you can buy in a store, and you'll build priceless skills in the process. Don’t rush the process — take your time with joinery and finishing, and you’ll end up with a bench that’s both functional and beautiful.